- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Careers

- Suppliers

- Contact Us

- IFI Connection

- Search

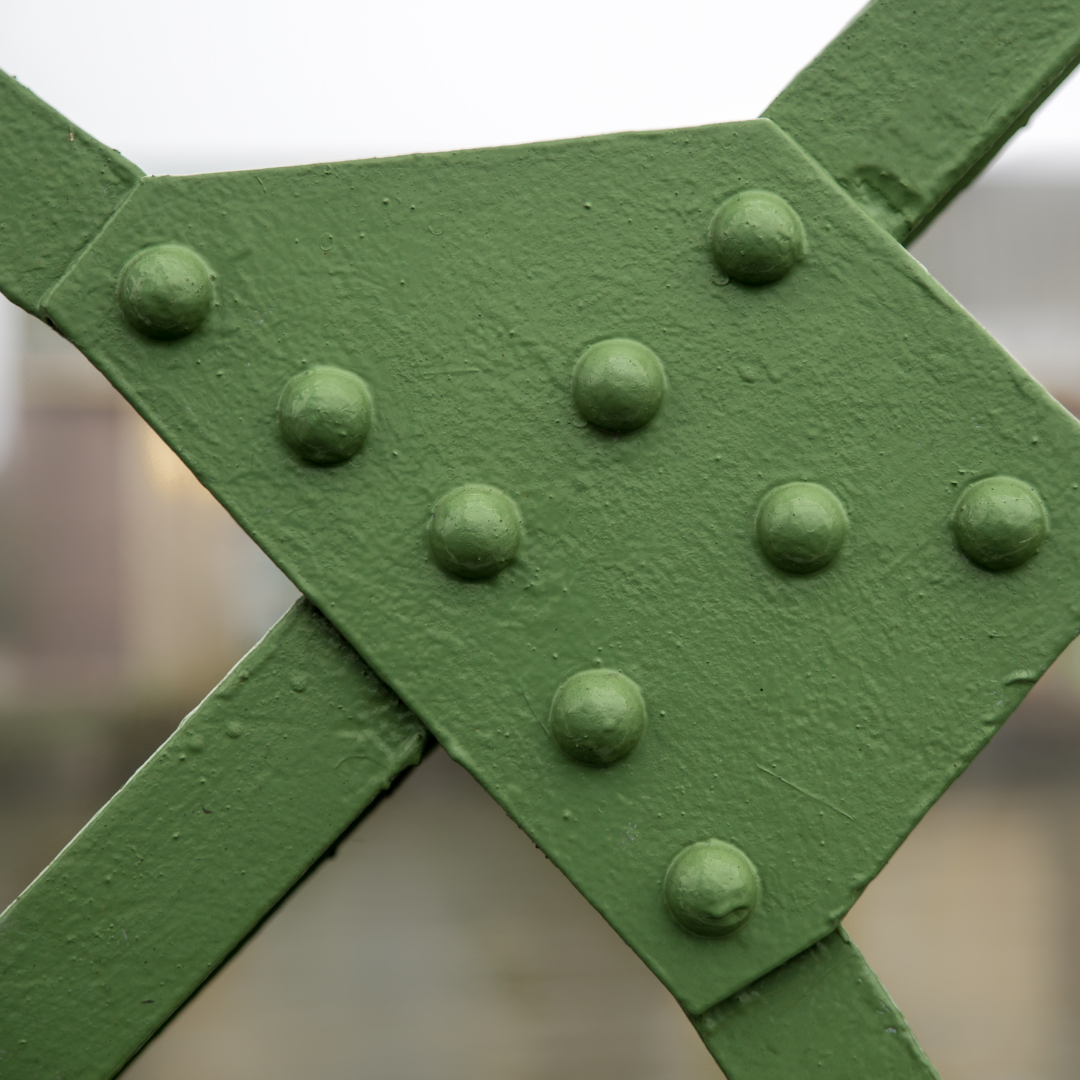

Challenge While at a customer facility, a Field team member observed that a percentage of double ended studs were exhibiting external strip out during assembly. This resulted in the entire sub assembly having to be scrapped.

Read More

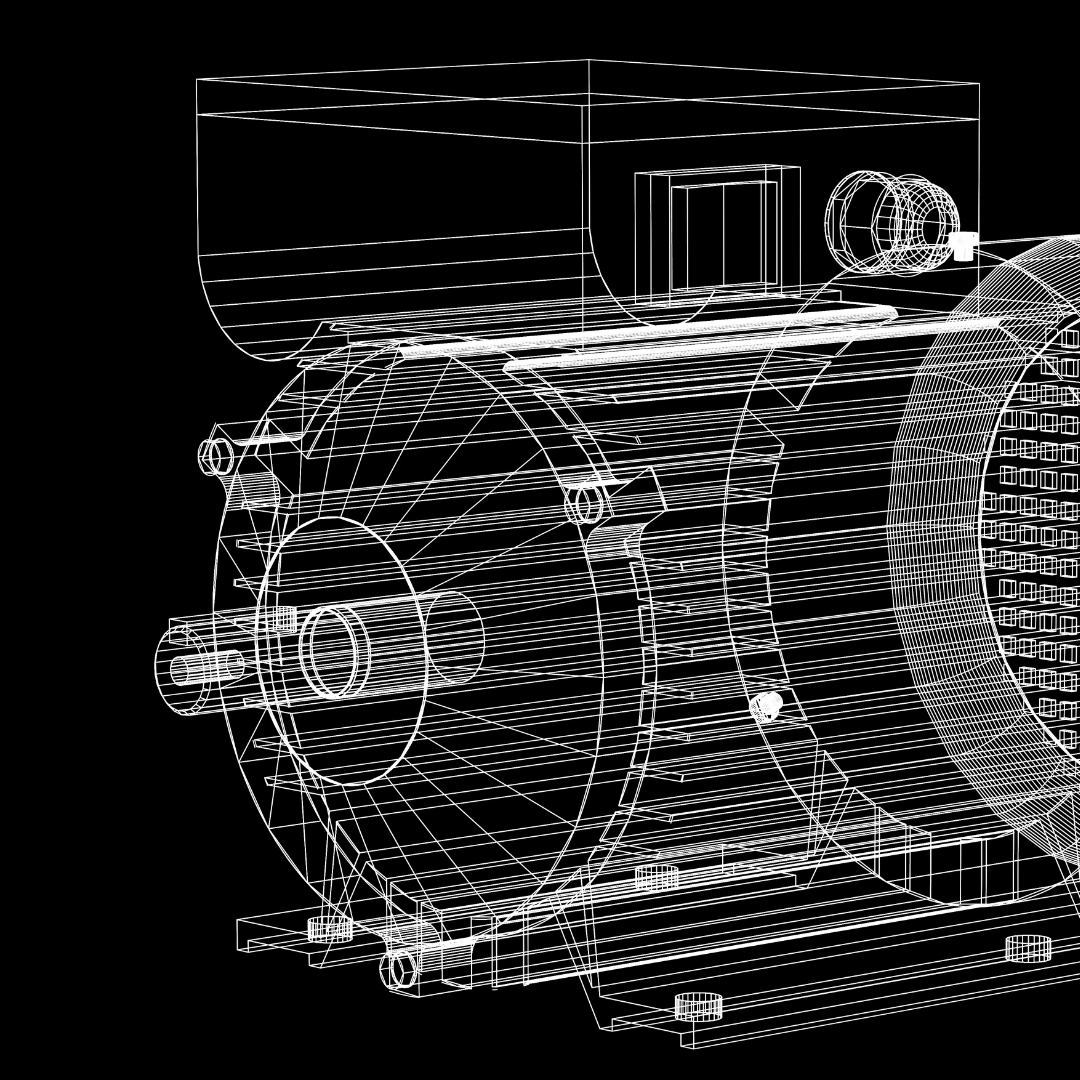

Challenge The Field team informed a customer of the high risk of internal hydrogen embrittlement on a series of grade 12.9 zinc plated socket head cap screws which they were using in electric motors. These parts had seen failures in the past, and going forward Field did not want such risky parts to be used anymore.

Read More

THE FIELD ENGINEERING TEAM SUGGESTED AN ALTERNATIVE MANUFACTURING PROCESS RESULTING IN A PIECE PRICE SAVINGS OF $33,310 ANNUALLY. Challenge Field received a request from a current customer to provide a quote for an expensive kit that contained four pieces of a stainless steel custom fastener with a “D” shaped head. The kit was identified as an item that needed to be supplied at a lower cost.

Read More

ENGINEERING REVIEW AND PART REDESIGN YIELDS $75,390 PIECE PRICE SAVINGS Challenge During a technical line review at a prospective customer’s facility, the Field engineering team observed a cumbersome and time consuming assembly process to a three component diaphragm. Upon further evaluation of the part, the Field team discovered that the manufacturing process to make these components was costly ...

Read More

Challenge During an assembly line review with a potential customer, the Field team noticed that a considerable amount of meter boxes were being scrapped and removed each day. Upon further review of the assembly process, the team observed that the workers were having problems with tapped thread quality and recess damage.

Read More

Challenge During an internal lean audit at Field, a team member was reviewing the frequency of transactions associated with a small group of fasteners being used by one customer. The team member discovered the number of transactions was inconsistent with the value of the product. The customer was managing a Kanban program internally and was shipping low dollar items on a regular basis and ...

Read More

RETHINKING THE ROLE OF SUPPLIER TECHNICAL SUPPORT Challenge The Field Engineering team provides hundreds of line reviews, product tear downs, and other technical support services every year to identify cost savings for our customers. The challenge is getting the cost savings implemented because fastener/ fastening issues are generally a low priority.

Read More

Observations and Solutions During a technical line review of a customer’s facility, the Field team observed the components and methods of manufacturing used to assemble an engine. The following observations were made with corresponding solutions:

Read More

CROSS FUNCTIONAL TECHNICAL TRAINING BENEFITS CUSTOMER WITH A TOTAL SAVINGS OF $73,193 Observation and Solution Upon reviewing a customer’s request for a quote for new parts, a Field account manager discovered several parts being ordered had a special plating request. The plating requested was a high end organic finish that would provide a great resistance to corrosion, but would require multiple ...

Read More

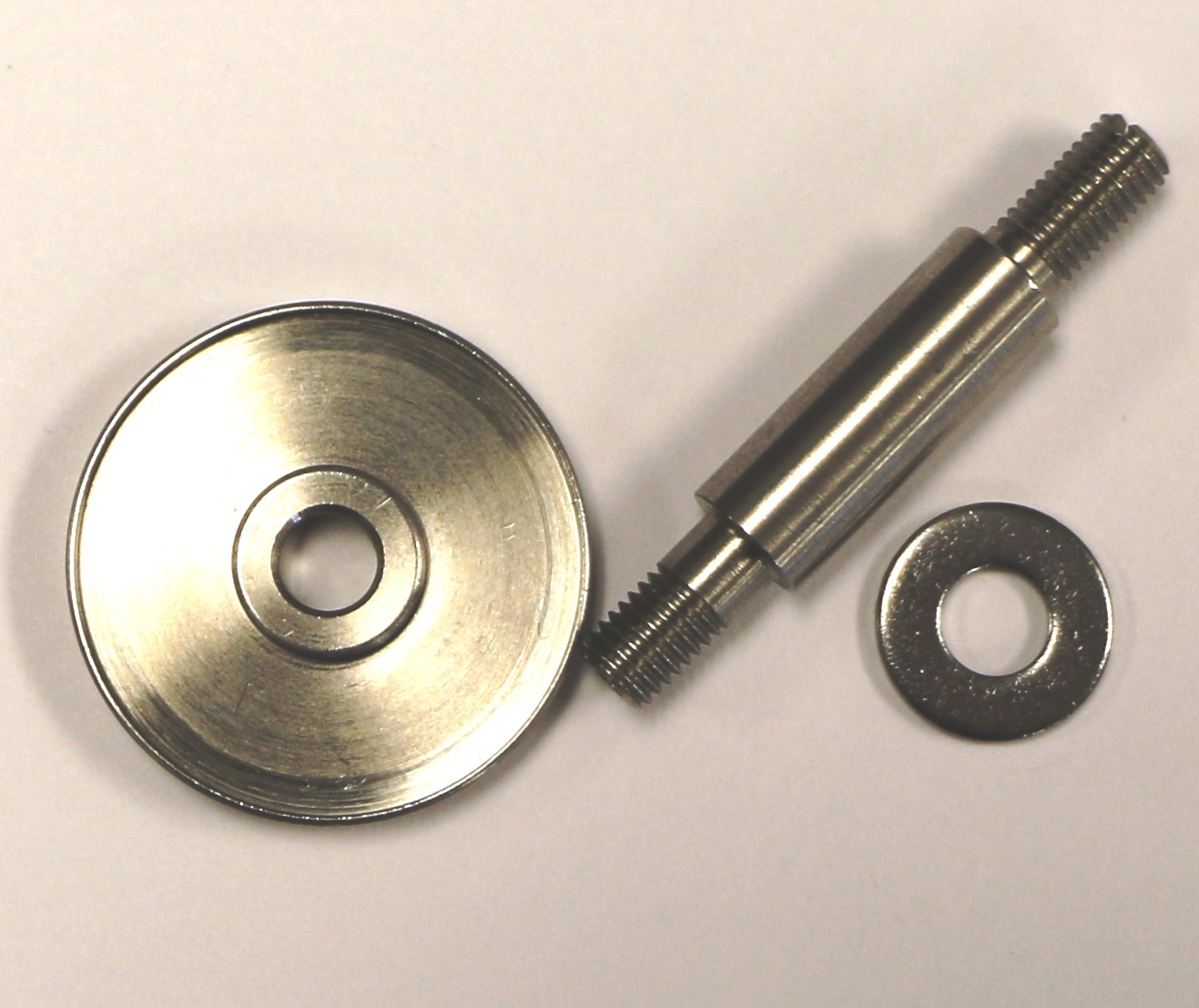

FIELD REDESIGN AND PROCUREMENT YIELDED $32,700 IN TOTAL SAVINGS Challenge The Field team initiated an engineering review of a customer’s product that revealed a problem they were having with a specific part. The machined part was subject to occasional cracking, due to the notch-sensitive nature of parts produced by the screw machining process. Part dimensions needed to be largely maintained due ...

Read More

Challenge Field’s customer was facing strong cost pressures as the only domestic manufacturer of their electronic products. Based on recommendations from Field on similar products, the large number of brass inserts and machine screws were targeted for evaluation. The current injection molded parts were designed with 32 brass inserts in thread sizes from 2-56 up to 6-32.

Read More

Challenge During a plant Gemba Walk with a current customer, Field observed an assembly condition and took steps to perform an Applications Problem Solving and Assembly Line Review of their manufacturing process when applying tape to pipe plugs and pipe nipples.

Read More